2018-07-27

GENERAL SAMPLE COLLECTION: CONSIDERATIONS AND TOOLS

一级样品收集:关注点和工具

Types of Systems andGeneral Considerations 粉体类型和主要关注点

homogeneous systems 均一粉体

For powder systems where the attribute of interest is uniformly distributed throughout the container—so that any sample is an unbiased representation of the entire container, lot, or population of interest—scoop sampling is adequate. Scoop sampling is a straight forward procedure in which the operator,after selecting representative containers for sampling, opens a container, scoops out a sufficient amount of material from the top of the powder bed, and then seals the container. If a thin layer of material on top of the powder bed is suspected of being different from the bulk, samples should be taken from a point below this top layer. For example, in cases of elutriation segregation, a thin layer of fine particles may lie on top of the powder bed, and the operator should dig down into the powder bed to avoid sampling from this layer. The scoop should be large enough that no material is lost during handling, because lost material may result in sample bias. In other words, one should avoid the use of a heaping scoop from which material can roll off the sides. The advantages of scoop sampling are convenience and cost, and, for highly potent materials, low-cost disposable scoops that can be used to minimize cross-contamination.

对于包装内特定(质量)属性均一分布的粉体,任何样品都完好的代表整个包装内、整批,或整体物料对应属性,因而舀取法是没有问题的。铲舀取样对于取样员是直接的方式,在选取了有代表性的包装后,他可以打开包装,从粉体上层舀取足够量的物料,然后执行包装封口。如果怀疑粉体表面有一薄层物料区别于整体,可以从顶层下面取样。比如,对于淘洗离散,一薄层的微粉可能在粉体上部,取样员应该下挖取到粉体内部以避免从这层薄层取样,而且取样勺应该足够大以避免物料在取样过程中丢失,因为过程中物料流失可能导致结果偏离。换言之,取样员应避免使用堆勺造成物料从侧面滑落。取样勺取样的优点在于简便廉价,对于高活性物料,一次性的廉价取样勺可以最小化交叉污染风险。

heterogeneous systems 非均一粉体

If the attribute of interest is spatially distributed in a heterogeneous manner throughout the sample, then scoop sampling is prone to potentially significant errors. Scoop sampling is a non-probabilistic method because only the most accessible fraction of the container is sampled. Obviously, only the material in the top layer can be reached with a scoop. For example, a sample from the top outer edge of the drum shown in Figure 3 could be biased because, in this example, the larger particles are preferentially distributed toward the top and outer edges of the drum. Hence the smaller particles have a lower probability of appearing in the sample. As aresult, the smaller particles will be underrepresented in the sample, and any analysis of particle size will not reflect the true particle size distribution of the original population.

如果被测属性在样品中存在不均一的空间分布,那么铲舀取样可能带来重大误差(错误)。铲舀取样是一种非随机的方式,因为只有包装内最易接近的区域会被取样。明显的,只有物料最顶层可以通过取样勺接触到。比如,图3中桶内上层外缘所取的样品可能是不具有代表性的,因为在这个例子中,大颗粒可能相对集中在顶部和桶外缘。因而小颗粒较低比例出现在样品中。由此,小颗粒未被样品充分代表,颗粒度分析结果不会反映原整体物料的实际粒度分布。

Forheterogeneous systems, the initial primary sample is the most difficult toobtain. Use of a sampling thief, sometimes called a grain probe or samplingspear, is needed. The advantage of a sampling thief is that much more of thepowder bed is accessible because the sampling thief can sample from differentpoints in the powder bed, thus helping to reduce sampling bias. Many types ofsampling thieves are available, including: (1) the concentric sleeve withslotted compartments, (2) the concentric sleeve with grooves, sometimes called theopen-handled probe, (3) the end sampler, and (4) the core sampler. Each typehas its own unique operating procedures, as described below.

对于非均一粉体,一级样品最难获得。采用刺入式取样器,有时叫取样标枪,是有必要的。这种取样工具的好处在于颗粒床的更大范围可以被取到,因为刺入式取样可以到达样品床不同的点以降低偏向性取样。市场上可以找到许多种刺入式取样器,包括:(1)含多隔室的同轴套入式取样器,(2)含细槽的同轴套入式取样器,(3)尾端取样器,以及(4)中心取样器。每一种有独立的操作程序。(具体操作程序略)

general considerations 主要关注点

The most reliable and reproducible results in powder size measurements are obtained when the particle size ranges from 2 to 10 µm; otherwise, the powder is too cohesive and does not flow properly into the sampling thief. In addition, particles larger than about one-third the width of the slot give poor results. Samples should be taken from several sites throughout the container. The probe should be long enough to penetrate at least three-quarters of the depth of the powder bed, ensuring that material from all depths can be captured in the sample. The choice of sites should be dictated by an understanding (often subjective) of the powder bed's degree of heterogeneity, which may have been caused by handling or movement during transport. Sampling plans can call for the insertion of the probe either at random locations and random angles or at predetermined locations and angles. For example, the plan may call for the probe to be inserted at the center and at two locations near the edges. Also,many operators recommend that probes always be inserted at a 10° angle from vertical, which increases the range of locations sampled.

当颗粒度在2-10um时,所获得的粒度结果可靠性和可重复性最好;然而,这些粉末结合紧密而不易流入取样器。另外,比凹槽1/3宽度大的颗粒所得结果不佳。样品应该从包装的多个点获取。取样器应足够长以达到粉体的不低于3/4深度,以保证各层颗粒均可被取到。点的选取应基于对粉体不均一度的理解(经常会是主观的),这种不均一可能由物料的处理和运输过程中的粉末运动导致。取样计划可以要求刺入随机点和随机角度,或到达预先指定点和指定角度。比如,取样计划可要求刺入中部和靠近边缘两点。也有很多取样员建议总是偏离10度角垂直刺入,这样可以增加取样区域范围。

Some of the disadvantages of sampling thieves include the labor-intensive nature ofthe procedure. The probe must be physically inserted into the powder bed, often multiple times; the contents of the probe must be emptied; and then the probe must be thoroughly cleaned. For settled powder beds, the sampling probe can be difficult to insert. In addition, the sampling probe can introduce errors as aresult of the following: fine particles can lodge between the inner and outer tubes; particles can fracture; fine particles can compact and not flow well into the sampling compartments; segregation can occur during flow into the sampling zone; and the act of inserting the probe can disrupt the powder bed by dragging powder from the top layers of the bed down through the bed.

刺入式取样器也有一些缺点,包括操作繁琐。取样器必须刺入粉体,经常很多次;取样器内容物必须清空;取样器必须彻底清洁。对于沉降粉体,取样器可能难以刺入。另外,刺入式取样器还可能由于下列原因导致一些不好的结果:微粒可能留存在套管夹层;颗粒可能破裂;微粒可能结团而不流入取样器;流入样品区时颗粒可能发生(二次)离散;而且取样器从上方刺入活动可能干扰粉体。

Representative Lot Sampling 有代表性的批取样

Statistically-based sampling plans are based on statistical principles and depend on the population’s spatial heterogeneity and intrinsic variability. Statistically-based plans are efficient and allow the collection of a sufficient number of samples to yield the desired degree of certainty without collecting too many or too few samples for the test method, scale, product variation, risk requirements, and tolerance for a stated product’s quality level or specification. The commonly used √N + 1 sampling plan given in Table 1 is not a statistically based sampling plan and may result in collection of too few samples for small populations and too many samples for large populations. The use of statistically-based sampling plans is advantageous because it facilitates risk management. However, in cases where prior knowledge of the population to be sampled is insufficient, a nonstatistical sampling plan suchas that given in Table 1 canbe considered.

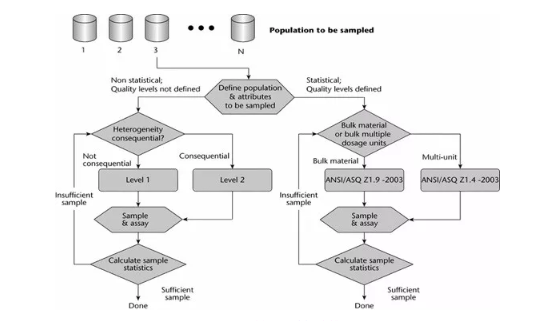

基于统计学原理的取样(简称:统计取样)计划要基于统计学原则,且要考虑整体的空间不均一性和(颗粒)内在离变。统计取样计划应允许收集多份(既不是太多也不是太少)样品以满足一系列因素的不确定度,这些因素包括方法、批量、产品变异、风险要求和特定产品质量水平/标准接受限度。表1中通常应用的 √N + 1 取样计划并非统计取样方案,可能导致对于少量物料收集太少样品,而大量物料又收集太多样品。应用统计取样计划是有益的,因为这种方式采用了风险管理。然而,如果对于待取样品基本信息不甚了了,则如表1的非统计原理的取样计划就可以考虑采用了。Figure 4 illustrates the sample size selection scheme paths. The first choice is whether to use a statistical or nonstatistical sampling plan. Statistical plans are preferred when a variable attribute like particle size or drug content is being determined. General sampling approaches are outlined in USP general information chapter Analytical Data—Interpretation and Treatment 〈1010〉.Statistically-based lot acceptance sampling plans require a valid rationale with known quality levels for the determination of product lot characteristics. As noted, the application of statistical sampling plans, including lot acceptance sampling plans, requires specific and thorough knowledge of the material being sampled. Reference statistical sampling plans state the rationale for sampling as part of the sampling scheme. Manufacturers who use astatistically-based lot acceptance sampling method should refer to an appropriate standard such as ANSI/ASQ Z1.9-2003 for bulk materials or ANSI/ASQZ1.4-2003 for multiunit or discrete populations. These standards are readily available via sources such as the American Society for Quality (http://www.asq.org/)or the American National Standards Institute (http://www.ansi.org/).

图4展示了选择样品量的路线图。首先考虑是否采用统计取样或非统计取样计划。当需检测变异属性,如颗粒度或药品含量时,则建议考虑统计取样计划。通用取样方法在USP general information chapter <1010> 分析数据--演绎和处理中有阐释。统计取样计划具体限度要求应基于有效的原理,这个有效原理建立在被测批产品已知的待测属性的质量水平上。如所提示,包括取样限度的统计取样计划的应用,要求对被取样物料信息有详细全面的掌握。还应把取样原理列入取样计划作为取样计划的一部分。应用统计取样的生产厂家可参考一个合适的标准,如针对散装物料取样的标准ANSI/ASQ Z1.9-2003 ,或针对多包装的分装物料取样标准ANSI/ASQ Z1.4-2003。这些标准可通过美国质量协会(http://www.asq.org)或美国国家标准中心 (http://www.ansi.org/)获取。

Figure 4. Sample size selection scheme. 样品量选择路线图

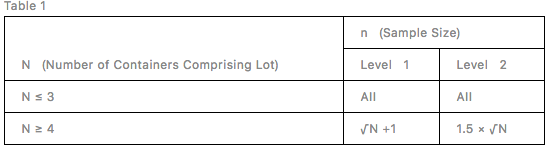

If one is developing a nonstatistical sampling plan for which the quality level is not known, Table 1 gives suggested sample sizes for the number of containers in the lot that should be sampled.

如果未知质量水平的情况下制定非统计学原理的取样计划,表1给出了推荐性的针对被取样包装抽样数量的要求。

The Level 1 sampling plan is relevant to materials when heterogeneity does not affect the analysis and the customer seeks to sample more than one container, when the sampling plan can be proportional to the square root of the number of containers received, and when the material comes from a known and trusted source. In such cases, the sample can be withdrawn from any point in the container. For adequately homogenous systems, scoop sampling from the top of the container is suitable.

水平1的取样计划适用于非均一性不影响分析的物料且客户会从一个以上的包装中获取样品,这种情况下取样计划(件数)可以与物料包装数的平方根成正比,该计划也适用于货源是已知可信赖的情况。针对这些情况,样品可以从包装内任何点获取。如果粉体充分均一,采用取样勺从包装顶部取样是合适的。

The Level 2 sampling plan involves a 50% increase in sample size when compared with Level 1 and is used when a larger proportion of the number of containers is needed, for example, when a material’s heterogeneity is suspected of being consequential and acceptance sampling quality levels are not defined, or when the material comes from a less trusted source. Depending on the material's degree of heterogeneity, a sampling thief may be used. However, if the degree of heterogeneity will not significantly affect the results for the attribute being sampled, then scoop sampling from the top of the drum may still be suitable.

水平2取样计划相对于水平1提升了50%的样品量,且在更多包装数的情况下应用。比如,当一种物料的不均一性被认为关键且待测质量限度水平未定的时候,或物料并非来源于一个可信赖的渠道。取决于物料的不均一性程度,可考虑采用取样器。但是,如果不均一性的程度并不显著影响质量属性的分析结果,则上层舀取样品仍可认为是合适的。

Table 1 shows the number of containers, n, to be sampled for a lot segregated into N containers. Note that the value of n from the formula is rounded at 0.5 up to the next higher integer. For example, if N = 6: for Level 1, n= √6 + 1 = 3.45 rounds to n = 3; for Level 2, n= 1.5 × √6 = 3.67, which rounds to n =4.

表1展示了样品包装数目,n,代表整批分散到N个分包装。注意公式中n值逢5方进位。比如,如果N=6,则根据水平1,n = √6 + 1 = 3.45 ,修约为3,根据水平2,则n = 1.5 × √6 = 3.67,修约为4(译者按:全进位法则在国内是可取的,适于口算而不必精确到小数点后一位).

Table 1

These initial decisions, as illustrated in Figure 4, are often difficult and sometimes must be made without sufficient information. If there is uncertainty about which method or level is appropriate, sometimes a quick, small-scale informal test of the system may help determine the best way to proceed. In addition, for some systems and attributes, the Level 1 and Level 2 sampling plans may result in over sampling. For example, when one is sampling for identification from the same lot, the suggested levels may result in collecting more samples than are statistically needed; in such cases, the statistically-based sampling plans referenced in Figure 4 canbe used.

做出如图4中的这些初始决定,经常并不容易,有时候还必须面对缺乏充足信息的情况。如果对于方法和水平的适合性存在疑虑,有时候快速的、小规模的非正式体系测试可以帮助决定应采用的最佳方式。另外,对于有些体系和待测属性,水平1和水平2取样计划可能导致过度取样。比如,整批取样鉴别,建议水平可能导致收集比统计所需更多的样品;这些情况下,推荐使用如图4的统计取样计划。

Sample Collection 样品收集

Acquiring a representative sample from a lot of bulk powder is a difficult procedure that requires special consideration, and the basic procedures for acquiring are presentative sample are discussed below. Note that every situation requires techniques that are appropriate for the given population to be sampled. The methods presented here are applicable to the sampling of static powders stored in midsize bulk containers such as 1-ton super sacks, 50-kg drums, or 50-lb bags. These methods are not necessarily applicable to the sampling of liquids, large storage containers such as train cars or silos, or in-process systems such as blenders or moving conveyer belts. In addition, the procedures described here are most applicable to particles in the size range from approximately ~1 µm to approximately ~1000 µm. Significantly smaller or larger particles require special procedures that are not covered here.

从许多散装粉末中获取有代表性的样品并不容易,需要专门思考,以下讨论获取有代表性样品的基本程序。请注意每种情况都要求取样技术应适合于指定的物料整体。此处所提供的方法适用于取中等体量包装中存储的静态粉末,比如1吨袋,50kg桶,或50磅袋。这些方法不必适用于液体取样,大体量包装取样,如火车皮、粮仓,或在线系统,比如混料罐,或移动的输送带取样。另外,此处所描述程序最适合大约1µm到1000µm粒度范围的颗粒。显著高于或低于此范围的颗粒需要特殊程序取样,本处方法并不适用。

PRIMARY SAMPLE COLLECTION 一级样品收集

Lot acceptance samples are generally transferred or delivered in containers. To collect a representative primary or gross sample (see Figure 1), the appropriate container or containers must first be selected from the population of N containers; second, a representative sample must be withdrawn from each of the selected containers.

批放行检验样品一般通过包装转运,为了收集有代表性的一级样品或总样品(见图1),必须首先从物料的N个包装中挑选合适的个体。然后从被挑选的(多个)包装中取出(并形成一个)有代表性的样品。

Container Selection 包装挑选

To avoid bias and other sampling errors, the containers to be sampled must be randomly selected. To make a random selection, first number all containers in the lot, then use a random number table (or computer-generated random numbers) to choose from which container or containers to withdraw the samples.

为避免偏选或其他取样误差,被取样的包装应随机抽选。为保证随机性,可首先给批包装编号,然后使用随机号码表(或计算机生成随机号码)来选择从哪些包装中抽取样品。

For systems in which containers are grouped together in such a manner that many of the individual containers are not practically accessible (e.g., 50-lb bag sstacked and bound in shrink wrap on a pallet), the sampling plan may need to take into account the larger container, in addition to the smaller container, as a sampling unit, in order to ensure a representative sample.

对于很多成组放置在一起,导致很多单一包装不易接触的体系(比如,50磅袋堆积和被热缩塑料袋捆扎在一个托盘上),取样计划可能需要将大点的包装加小点的包装记为一个取样单元,以保证获得有代表性的样品。

Withdrawing Sample from a Container 从包装中取出样品

container types 包装类型

The three most popular container types are the bag, drum, and super sack. Because bags are generally closed and not resealable, special sampling thieves, sometimes called bag triers, have been designed to puncture the bag. If the system to be sampled is heterogeneous, the samples should be obtained from the bottom, center, and top of the bag; and, depending on how the bags are stacked on the pallet, they should also be sampled from the front and the back. When sampling from bags, particular attention should be paid to the corners, becausethey can disproportionately trap fine particles. If no bag trier is available,use a knife to cut open the bag for sampling. When sampling from a bag, be sure to clean the external surface sufficiently that the sample is not contaminated and foreign material is not introduced into the bulk material. Once the sample has been taken, place a compatible material over the hole in the bag, then fix this patch with an appropriate adhesive tape. Depending on the heterogeneity of the drum, a scoop or a sampling thief is used. Super sacks are large sack containers that usually have a fill spout on the top and a discharge spout on the bottom. For adequately homogeneous material, scoop sampling is appropriate;but if there is any concern about the heterogeneity of the material, a thief should be used. The large size of super sacks makes the use of a thief more important for representative sampling than in the case of a drum or bag, in order to limit potential delimitation error.

三种最典型的包装类型是袋、桶,和大吨袋。由于袋子一般是封好的而且不可再封,刺入式取样器或叫破袋枪被设计用来刺透袋子。如果被取样的粉体是不均一的,样品应从袋子的底部、中部和上部获取;还应考虑袋子如何堆放在托盘上,并从其前面和后面也抽取样品。当从袋子中取样,应特别注意角落,因为这些地方可以不成比例的捕获微粉。如果没有刺入式取样器,可以用刀割开袋子取样。当从袋子里取样,注意充分清洁袋子外表面以避免交叉污染或引入异物到物料中。一旦取样完成,在袋子刺破口放入兼容物,然后用合适的胶布封闭这个补丁。取决于桶内的不均一度,取样勺和取样器其实均可选用。大吨袋通常会在上部有注入口且在下部有流出口。对于充分均一的物料,取样勺就可以了;但是如果对于物料均一性有疑虑,则应采用刺入式取样器。为了获取代表性样品,相对于袋子或桶,大吨袋的尺寸使刺入式取样器的应用变得重要,它可以控制潜在的分界误差。

Sample Handling 样品处理The samples collected can be either assayed individually or combined; then a subset of the gross sample can be assayed, as depicted in Figure 1 and described below. Sample increments should be combined on a clean, dry surface or in a suitable container or bag. All containers with which the sample comes into contact should be inert and should not chemically or physically react with the sample. In addition, samples should be accurately labeled and good records kept. A portion should be kept for possible future analysis.

所收集的样品可以分别检验,也可以合并;然后(合并后的)一个二级样可以用于检验,如下文图1所示。样品合并应在清洁、干燥的表面、合适的容器或袋子中进行。样品所接触的所有包装应该保持惰性且不和样品发生物理或化学反应。另外,样品应被准确标识和保存好相关记录。应有留样以供未来可能的分析使用。

PRIMARY SAMPLE SIZE REDUCTION 缩减一级样品量As mentioned above, the primary sample typically consists of multiple samples taken from containers and mixed together. To obtain an analysis or measurement sample (Figure 1), the gross or primary sample must be reduced to a size appropriate for the analytical method. Gross or primary sample size reduction is an often overlooked as pect of a sampling plan, but it is an important step. The factors that cause segregation in a container can also cause segregation in the primary sample, and any bias in the size reduction method for the primary sample will lead to erroneous results. The advantage of secondary samples is that the mass has been reduced to a point at which it is much easer to obtain are presentative sample because every element in the powder bed is readily accessible. Such accessibility makes it easier to adhere to sampling best practices. Generally speaking, sample measurement takes place under either wet or dry conditions; the choice is dictated by the requirements of the analytical method. For example, the Coulter counter requires that samples be uniformly suspended in an electrolyte, but other methods, like sieving, are typically performed with dry powders.

如前所述,一级样品通常由来源于不同包装中的许多样品混合而成。为了获取分析样品(见图1),总样品或一级样品必须缩减到合适的样品量以适用于对应的分析方法。总样品或一级样品缩减经常是取样计划中被忽视的一个方面,但却是个重要的步骤。在包装内导致离散的因素在一级样品中同样可能出现,一级样品量缩减方法中的任何偏离都可能导致错误的分析结果。二级样品的好处在于重量已经减低到容易获得有代表性样品的程度,因为每个粉体的部分都容易获取。这种易获取性使落实优良取样法则变得简单。一般而言,样品检验在干或湿的背景下进行;这种选择由分析方法本身的描述限定。比如,粒子计数器要求样品均匀分散在电解液中,而其他方法比如筛分法,一般以干粉的形式被检测。Before dividing an agglomerated sample, the agglomerates should be broken apart by asuitable technique such as sieving.

在分离团聚样品之前,团聚应被适当的方式破碎,比如过筛。

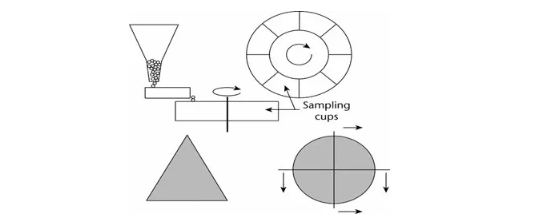

Dry Analysis Methods 干法分析方法(的分样)Many laboratory devices are available for the reduction of the primary sample to ananalytical sample. The three most important methods used in the pharmaceutical industry are: (1) scoop sampling, (2) cone and quartering, and (3) the spinning riffler or rotary sample divider (manual method of fractional shoveling); see Figure 5.

许多实验室装置可以用于一级样品量缩减为二级样品量。制药工业中最重要的三种方法是:(1)舀取分样法,(2)锥体四分法,和(3)旋转槽分样法或旋转分样器分样(人工铲样细分方法);见图5.

Figure 5. Two procedures for dividing samples. Top: spinning riffler, in which a circular holder rotates ata constant speed, and the sample is loaded at a constant rate into the containers via a vibratory chute, which is fed by a mass-flow hopper. Bottom: cone and quartering. (Cone, left, is flattened and quartered; quarters can be formed into cones and further subdivided.)

图5. 两个分样程序。上面的:旋转槽分样法,其中有一个旋转槽以恒定速度转动,样品以恒速从漏斗中流下并从斜坡振落到旋转槽中。下面的:锥体四分法(左边锥体摊平后四分;每个四分体可以再形成锥体二次四分)。

scoop sampling 舀取分样法

Scoop sampling is done as previously described, but generally with a smaller scoop orspatula. Great care must be taken when removing material from the primary sample, because this material could be highly segregated as a result of handling. Scoop sampling is appropriate for homogeneous or cohesive powders. However, if the powder is prone to segregation, scoop sampling can introduce significant errors. Moreover, scoop sampling has several serious disadvantages. First, the method depends on the operator’s deciding from which part of theprimary sample to scoop the material and what quantity of the sample toextract, which are features that can introduce operator bias. Second, in scoop sampling, operators have a natural tendency to withdraw the sample from the free surface, which is highly prone to segregation and is not representative of the bulk. Third, operators need to avoid creating a heap where rolling segregation can occur, because material could fall off the edges of the spatulaor scoop and bias the sample. Ideally, the operator should make some attempt to mix the primary sample before using the scoop, but this too can exacerbate segregation problems and should be done only with great caution.

舀取分样已如前所述,只是通过勺子或铲刀即可完成。在从一级样品中转移物料的时候一定要非常注意,因为这些物料在处理过程中容易发生高度的离散。舀取分样法适合于均一的和有黏着力的样品。但是,如果粉末易于离散,舀取法可能引入重大误差。而且,舀取法还有几个显著缺点。首先,这个方法取决于操作员决定由什么部位取多少样品,而这个过程容易带入操作人员的主见。其次,舀取分样中,操作人员有自然的倾向从自由面取样,而自由面极易离散且对于整体不具有代表性。第三,操作员需要注意避免制造堆积以防止滚落离散,因为物料可以从取样勺边缘滚落从而使样品失去代表性。最理想的,取样员应当在用舀取法之前尝试混匀一级样品,但是这也可能加剧离散问题,因而要非常之小心。

cone and quartering 锥体四分法Cone and quartering is done by pouring the primary sample into a symmetric cone on a flat surface. The cone is then flattened by a flat surface such as a spatula,and is divided into four identical quarters (Figure 5). One quarter is taken as the sample. This procedure can be repeated (e.g.,quarter-samples can be subdivided into quarters) until the desired sample sizeis obtained. The theory of this method is that when a symmetric cone is created, all the segregation processes also occur symmetrically around the cone, and hence symmetry is used to mitigate the effect of segregation. In practice, it is very difficult to actually make a symmetric powder cone, and the method becomes very operator-dependent and often unreliable. Differences in how operators form the heap and subdivide it can lead to a lack of precision and significant errors. In addition, if the method is done more than once, errors can propagate each time the cone and quartering is performed. Some experts do not recommend this method.

锥体四分法首先应把一级样品轴对称堆积在平面上。然后用铲刀把堆体摊平,分隔成四份(见图5).其中一份作为样品。本过程可以重复(比如,单份四分样品可以二次四分)直到获得预期体量的样品。本方法的理论在于一旦形成对称锥体,所有(常见)离散均围绕锥体对称存在,因而对称因素被用来降低离散效应。实际执行中,形成对称的粉末锥体非常困难,且本方法非常依赖于取样员而经常可靠度较低。(不同)操作员在如何形成锥体上和如何再分上的不一致,都可能导致准确性缺失和造成重大误差。另外,如果方法被执行多次,误差可能伴随形成锥体和四分操作的过程累积。有些专家并不推荐本法。

spinning riffler 旋转槽法As pinning riffler (Figure 5) includes a series of containers mounted on a circular holder. The circular holder rotates at a constant speed, and the sample is loaded at a constant rate into the containers via a vibratory chute, which is fed by a mass-flow hopper. Once the material has been divided among the different holders, an individual holder can be removed for testing or further sample division. The angular velocityof the circular holders and the amplitude of the vibratory feeder can be controlled to accommodate powders with different flow properties. The holder velocity and feed rate should be adjusted so that the containers fill uniformly and so that a heap does not form on the vibratory feeder. Spinning rifflers are available in different sizes, making possible subdivisions of powders ranging from a few milligrams to hundreds of grams. The only drawbacks of the spinning riffler are the time required to process the sample and clean the device, and the capital expense. Despite these minor disadvantages, the spinning riffler isby far the best method for subdivision of free-flowing powders.

图5旋转槽包括一系列在旋转器上放置的小盒。旋转器恒速旋转,样品以恒速从漏斗落下,再通过振动斜坡落入小盒。一旦物料被分散到不同的盒子,某个单一的盒子可以被取下作为样品,或进行进一步的分离。旋转角速度和振幅是可控的,以适应粉末不同的流动性。支撑器的旋转速度和漏斗下料速度应调整到合适,保证小盒被均匀装料,且振动斜坡也不会堆积样品。旋转槽有不同的尺寸,可以适应几毫克到数百克样品的二次分离。唯一缺点就是需要时间处理样品和清洁装置,并且价格较贵。除了这些小缺点,对于流动性强的粉末这是远胜于其他的最佳分样方法。Fractional shoveling is the manual version of the spinning riffler. In this method, scoop samples are taken from the original sample and placed into a sufficient number of aliquots, and then subsequent scoops are taken from the original sample and placed into one of the aliquots in sequential order. This process is repeated until the original samples are gone. Then one of the aliquots is randomly taken as the reduced sample. As is the case with all manual methods, operator error and variability can be significant factors.

片段铲分(旋转分样器法)是旋转槽的手工版本。本法中,从原样中铲取样品,平均配置到足够的(旋转)小格中,然后再次从原样中获取样品并同法按序配置,直到原样分配完毕后随机取出一份作为二级样品。由于本法中所有操作人工完成,操作误差和变异可能成为重要影响因素。Wet Analysis Methods 湿分析法(的分样)Wet analysis methods require dispersing the sample in a liquid suitable for analysis, and then withdrawing an aliquot using a syringe or pipet. Effective secondary sampling requires making a stable homogenous suspension (i.e., the sample must be stable from the time of formation of a suspension to the time when the analysis is complete). Some important factors in wet analysis are sample solubility in the dispersion vehicle, aggregation of sample, the use of suspending agents, and deaggregation of primary particles in the dispersion vehicle. Even though a uniform suspension is created, the sample should b ehomogenized, typically by shaking, immediately before withdrawing the sample with a syringe or pipet. The diameter of the syringe or pipet should be large enough so that particles are not excluded and clogging does not occur. The diametersof the largest particles should not exceed 40% of the syringe or pipet tip diameter. If for practical reasons the amount of material from the primary sample is too large, the sample size should be reduced before a suspension is made. To reduce the sample size, use the methods described above in the Dry Analysis Methods section. As a precaution, collect and retain enough sample to repeat all tests a minimum of five times.

湿法分析要求在合适分析操作的液体中分散样品,然后用注射器或吸管获取等份。有效的二级样品分样要求形成稳定的均匀悬液(即,样品必须从形成悬液开始保持稳定,直到分析完成)。湿法分析中有些重要因素,如样品在分散介质中的溶解度,样品团聚,分散剂的选用,分散介质中的一级颗粒的解聚集等问题。尽管形成了均相,在抽取样品前还是应该立即进行混匀,通常是振摇的方式。针管或移液管的直径应足够以快速吸取颗粒而不堵塞。最大颗粒直径不应超过40%的针孔或移液管尖直径。如果因操作原因,一级样品物料量太大,样品量应在制备悬液前降低。为了降低样品量,可参考使用干分析法的分样部分所介绍的方式。作为防控措施,建议收集和获取足够样品并重复测试不少于5次。