2018-05-13

【译者心语】:取样永远是第一步的!

样品的代表性直接影响分析结果的可靠程度。如何合理取样?发生OOS又如何做取样环节的调查?大家常常并不重视取样的细致合理化,出现问题又常常无从着手,难以判断和下有指向意义的结论。这篇USPGIC文章从固体物料离散理论、取样工具、取样和分样方式着手,体现各种具可操作性方法的优点同时也客观阐述不足。与其说是给我们灌输知识,不如说是引导我们形成有代表性取样问题的良好思考习惯。如果仔细阅读,还会发现一些我们习以为常的细节处理不一定合理或是最佳方式。

遍布公式、术语的文章翻起来累,读起来也累!建议有兴趣的亲们分2-3次在闲暇时细品,篇幅较长,为便于阅读,译者已在精彩处以粗体字标出。为提升阅读的流畅度,原文中取样工具操作方法的具体介绍和三个附录部分内容未引入,有兴趣的读者可再回溯原篇。

<1097> BULK POWDER SAMPLING PROCEDURES

<1097> 散装粉末物料取样规则

INTRODUCTION 介绍

The goals of this chapter are to provide guidance on bulk powder sampling procedures, identify important bulk powder sampling concepts, and collect a knowledge base of useful practices and considerations that can lead to the ideal physical sampling of bulk powder materials. The terminology used here is well established in the field of material sampling (see Appendix 3, for instance reference 7). Sampling is undertaken as part of an estimation process. The parameter of primary interest here is the mean level of some analyte in the bulk powder as a whole.

本文的目的,在于为散装粉末物料提供取样程序指南。包括明确散装粉末样品的重要取样原则,形成基于科学知识的适用操作模式和思考方式,以实现理想的散装粉末物理取样。本文相关术语在物料取样领域实践中逐步形成(见原文附录3,如第7条)。取样其实是整个评估测试过程的一部分,散装粉末物料取样中首个要点在于获取被分析物的平均水平。

The purpose of a sampling plan is to obtain a representative sample of a population so that reliable inferences about the population sampled can be drawn to a certain level or degree of confidence. Acquiring a representative sample from a lot is critical because without a representative sample all further analyses and data interpretations about the lot are in doubt. An ideal sampling processis a process in which every particle or at least every equal-size portion of the population has an equal probability of being chosen in the sample. In addition, sampling procedures should be reproducible, i.e., if the sampling protocol were repeated, a high probability should exist of obtaining similar results. Also, the integrity of the sample should be preserved during and after sampling. The details of how to sample depend on a variety of factors. For example, criteria for sampling to evaluate particle segregation may differ from criteria for evaluating moisture content or identification.

制定取样计划的目的在于从物料整体中获取有代表性的样品,以保证所取样品的可信性达到一定水平或一定置信度。从批物料中获取有代表性的样品至为关键,因为无此前提则所有关于此批物料的后续分析和数据演绎皆可能被质疑。合理的取样过程应保证每个个体颗粒,或至少整体的每个平均分部有相同的几率被取为样品的一部分。此外,取样程序应具有可重复性,即,如果取样方案被重复执行则很大几率应得到相似的测试结果。还有,样品的完整性在取样过程中和取样完成之后均应有保证。(最后),如何取样的细节也依赖于各种因素,比如用于颗粒分布的取样要求应和用于水分检测或鉴别样品的取样要求有所区别。

Because of the propensity of a powder to segregate, heterogeneous powder systems can make it difficult to obtain an ideal sample. Thus, to extract representative samples requires careful development of a sampling plan that accounts for and mitigates the segregation tendencies of a particular powder system. Developinga general guidance for bulk powder sampling is challenging because every situation is different, and therefore different approaches must be used to deal with each situation. Thus, the goal of this general information chapter is to outline recommended steps for developing a sampling scheme or plan for aparticular system that is consistent with good sampling practices.

由于粉末具有离散特性(译者注:所谓离散特性,其实就是“尘归尘、土归土”的颗粒运动趋势),从不均一的粉体获取理想的样品并不容易,因此,需要制定能够反应和减轻粉体离散趋势影响的取样方案来获取有代表性的样品。制定一个粉末物料取样的通用指南具有挑战性,因为面临的具体问题往往不一样,客观上就要求针对不同的情况制定不同的方式方法。因此,本通用资料篇(GIC)的目的也在于为特定的系统给出制定取样计划的推荐步骤,以符合规范合理化取样的要求。

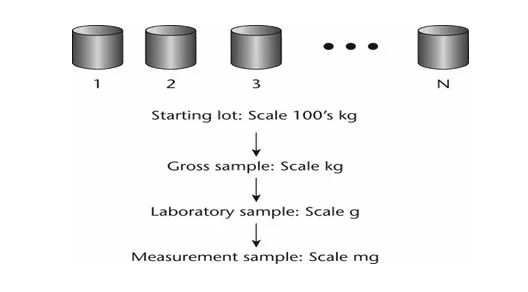

The primary difficulty in acquiring a representative sample is that the size of the sample for measurement, typically a few milligrams to grams, must be withdrawn from a large population on the order of hundreds to thousands of kilograms. The few milligrams analyzed in a laboratory must be taken from a large population of particles in a warehouse in such a manner that the measurement sample is representative of all the particles in the lot. Any bias or error in the sampling process will cause all future inferences to be in error. Over the years methods have been developed and refined to attempt to ensure that the measurement sample is representative of the whole population. A typical strategy is shown in Figure 1. The strategy is to sample in stages, starting with the initial gross or primary sample withdrawn directly from the received containers. In the laboratory, the gross sample must be reduced in size until it is the appropriate size for measurement. This should be done in a manner that minimizes the introduction of sampling errors. The key to reducing the sampling error is to ensure that every particle of the population has an equal probability of being included in the sample. However, because of segregation or the non random nature of powders, many obstacles can cause bias and contribute to sampling errors. Following the flow chart in Figure 1 andthe steps outlined in subsequent discussions will help to minimize sampling errors.

实现取样代表性的首要困难在于,用于分析的样品常常只有几毫克到几克,而这有限的样品需要从几乎成百上千公斤的大批物料中获取。这几毫克实验样品必须以有代表性的方式从仓库中该批物料大量的颗粒中取出,取样中任何偏离或差错都可能导致相应分析结果错误。往事如歌,很多方法被优化和改良以尝试保证分析样品对于整体的代表性。一个典型的策略见图1,策略是分步取样,从直接在所接收的容器中获取初始样或一级样开始。在实验室,该一级样品必须减少到适合检测的(二级)样品量,这个过程应最小化可能引入的取样误差。最小化误差的关键则在于保证整体中每一颗粒有均等的机会被引入最终样品。然而,由于颗粒具有离散性和非随机特性,很多障碍可能导致偏离从而形成取样误差。流程图1和后续的相关步骤讨论,就会专注于最小化各种取样误差。

Figure1. Overall sampling strategy for reducing the sample size from the hundreds of kg scale to the mg scale.

图1. 从百公斤级到毫克级取样整体策略

To acquire a representative sample, a suitable sampling plan must be developed and implemented. A good sampling plan includes: (1) population determination and sample size selection, (2) a sample collection procedure and a method for sample size reduction, and (3) summary calculations that demonstrate that the sampling plan will yield samples that accurately characterize the population to within a stated level of acceptance. In addition, an infrastructure is needed to maintain the integrity of the samples and sampled materials.

要获取有代表性的样品,必须制定和执行合适的取样计划。一个良好的取样计划包括:(1)明确总量和确定样品量,(2)制定(一级)样品采集程序和(二级)样品量缩减方法,以及(3)综合计算以证明按照取样计划所获取样品可以在置信限度内准确表达整批物料。另外,也应建立可以保持物料和样品完整性的基础条件。

This chapter begins with a brief introduction to sampling theory and terminology. The technical content of the chapter requires a basic scientific understanding of physical particle characteristics (e.g., mass, density, shape, and size) and statistics (e.g., acceptance sampling and binomial distribution).

本文以取样理论和术语的介绍起篇。相关技术章节需要对于各种物理粒子特性(如质量、密度、形状、粒度)和各统计学概念(如抽样验收、二项分配)科学含义有基本理解。

SAMPLING THEORY AND TERMINOLOGY 取样理论和术语

Fundamental Sample Size(Sample Mass) 基本样品量(样品重量)

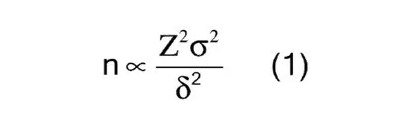

Sample size is considered from two perspectives: (1) the mass of the sample intended to represent the entire population, sometimes termed the composite sample, and (2) the number of samples taken with a mass sufficient to independently evaluate, compare, or provide confidence to ensure the reproducibility of the composite or the uniformity of the population. The key to obtaining an ideal sample is to understand and account for the degree of heterogeneity of the characteristic being evaluated in the system under study. For example, heterogeneity of a particle system arises from two sources: the intrinsic, constitutive, or compositional heterogeneity and the spatial distribution heterogeneity. The intrinsic heterogeneity of the powder system reflects the fundamental differences in the individual particles. Statistical heterogeneity (differences between individuals), or variance, is expected to maintain assumed properties. For a normal population the general expression for a statistical sample size suggests that the number of independent samples is proportional to the square of the normal quantile at the desired confidence level (Z) and the population variance (σ2) and is inversely proportional to the square of the minimum detectable difference required (δ), as shown in equation 1:

样品量应从两方面考虑:(1)用于反映整批物料的样品重量,有时也称样品组成,以及(2)足够的样本数量(个数),这些样本各具有一定量且可以进行独立评估、用于比较或提供证据以保证可以再现物料整体的组成或一致性。获取理想样品的关键在于努力理解和克服颗粒系统里待测属性的不均一程度。即,粉体不均一性其实是来源于两个途径的:一种是颗粒组成的,本质内在的不均一;另一种是空间分布的不均一。其中,粉体颗粒内在的不均一反映存在于个体颗粒内的根本的差别。而统计学不均一(个体颗粒间差异),或离变,则可望保留预想的(质量)属性。对于一般的整体而言,基于统计学原理的样品量通用公式为样本数量与预期的置信限水平(Z)平方和整体标准差的平方值(σ2) 成正比,与最小可识别精度(δ)平方成反比,见方程1:

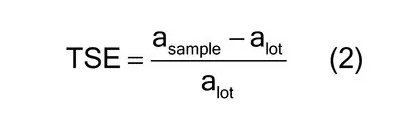

In order to apply the normal theory sample size equation to sample mass with adiscrete number of particles, consideration for material characteristics is needed. For a heterogeneous bulk material, such as a bulk powder, the sample mass required to ensure adequate representation of the intrinsic or fundamental population heterogeneity or variation is determined by the size, shape, and density of the particles. The total sampling error (TSE) measures the difference between the analyte concentration estimated in the sample (asample) and the mean analyte concentration in the lot (a lot) relative to the mean analyte concentration in the lot (alot), as shown in equation 2:

为了使一般样品量理论方程适用于粒度离散分布的样品,需要特别考虑物料的特性。对于不均一的整批物料,如整批粉末,为保证足以代表颗粒内在的不均一性或差异而所需的抽样数取决于颗粒大小、形状和颗粒密度。总取样误差(TSE)为被分析物浓度水平与整批浓度水平的差值,除以整批浓度水平,如方程(2):

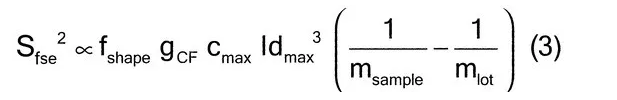

When ideal sampling is employed, the TSE is reduced to a fundamental sampling error, limited only by the intrinsic heterogeneity of the material. The relative variance of the fundamental sampling error (Sfse2) has been empirically estimated in particle size applications by characterizing the critical particle mass, heterogeneity, size (diameter), shape, density, and weights of the material. Empirical estimates require a thorough and complete knowledge of the material and process. Established material characterization and methods are critical aspects of avoiding unacceptable estimates. As shownin equation 3:

一旦实现理想取样,TSE将被降低到基本取样误差(fse)水平而仅局限于物料颗粒内在不均一。基本取样误差的方差(Sfse2) 已可以通过粒度软件从经验上估测,这种经验估测基于测定关键的颗粒集合、颗粒不均一性、粒径、形状、密度和物料量等等信息。经验估测要求对物料和工艺的全面彻底的了解。所确定的物料特性和所应用的方法是避免不可接受的评估的关键方面。具体如方程(3):

wheref shape is a measure of cubicity or shape factor of the analyte particles; gCF, the granulometric factor, is an empirical correction factor of differences inparticle size; cmax is the compositional maximum heterogeneity and is calculated as if the material consists of the analyte particles and everything else; l, the liberation factor, is an empirical factor representing the proportion of critical content particles separated from the non-analyte containing particles of the lot; dmax is the particle diameter [e.g., the maximum diameter or the diameter (cm) of the size of the opening of a screen retaining 5% by weight of the lot to be sampled]; msample is the mass of the sample; and mlot isthe mass of the lot being sampled. [Note—A liberation factor is needed when the analyte does not appear as separate particles. A high liberation value (1.0) suggests heterogeneity of particles. A low liberation value (0.05) suggests very homogeneous particles. See Appendix 1 for examples of potential applications of equation 3 in the estimation of the fundamental sample mass needed to account for constitutional heterogeneity of the powder mixture.] Use of equation 3 requires prior estimates of fshape, gCF, cmax, I,and dmax.

其中,fshape是被分析颗粒的立体或形状指数;gCF,是粒度指数,即颗粒间差异的经验校正因子; cmax 是组成的最大不均一性(以物料由被分析颗粒和其他所有颗粒组成的方式计算); l,释放因子,是经验指数,代表关键成分颗粒从该批非被分析物的颗粒中分离的比例;dmax 是粒径[如,最大粒径或过筛保留的整批物料5%的筛上物粒径];msample 是样品量;mlot 是被取样批次的总量。[注:当被分析物不是分离颗粒时,应赋予释放因子。高的释放值(1.0)代表颗粒不均匀,低的释放值(0.05)代表分布非常不均匀。见附件1(未译,参考原文)示例,方程3潜在应用于评估基本样品量时,需要考虑混合粉末的内在不均一]方程3的应用需提前评价 fshape, gCF, cmax, I, and dmax.

Segregation Error 离散误差

Distribution heterogeneity is the difference between samples or groups of particles spatially or temporally. For example, small particles are located preferentially in the lower portion of a powder bed. This type of situation can arise as a result of powder bed segregation and is common in some particle systems with a broad particle size distribution. In other words, smaller particles may not be randomly distributed throughout the lot. This spatial heterogeneity introduces variation in the sample and is a source of variation that contributes to the total variation. Together, fundamental and segregation error give rise to sampling error, which dictates how variable the samples will be, how large the sample size and numbers of samples should be (e.g., 10 containers, sampled at top and bottom, with sample sizes of 50 g each), and how hard it will be to obtain a representative sample.

分布不均一是样品或颗粒集合空间上存在的或暂时存在的离变。比如,小的颗粒会优先分布在颗粒床较低部分。这种状况会作为粉体离散的结果发生,且在一些具有宽粒度分布的粉体中很常见。换言之,小颗粒可能不会随机分布于整个批次。这种空间不均一性给样品引入离变并且构成整体离变的一个因素。内在误差和离散误差一起提升了取样误差,并决定了样品多大程度存在离变,决定了样品量应有多大,应取多少个样本(比如,10个包装,顶部和底部取样,样品量每份50g),以及获取一个有代表性的样品难度有多大。

Minimizing the effects of segregation error during lot material characterization while still ensuring a representative sample mass requires collecting many small samples that average out the variation of the segregation error. This assumes one is interested in estimating the overall average, not characterizing lot heterogeneity. Segregation error is difficult to control because segregation may be the result of changes in particle size, shape, and density, as well as inputs into the determination of sample mass. Minimizing the effects of segregation error when reducing the primary sample size requires adequate physical mixing or randomization of the primary samples before analysis, thus providing equal selection probability.

表征整批物料过程中要最小化离散误差影响的同时,又要保证有代表性的样品量,客观上要求采集许多小份样品以平均化离散误差的变异。这客观上要求着力估算整体平均值,而非表征整批不均一性。离散误差很不可控,因为离散可能作为颗粒度、形状、密度,还有用于测试的样品量变化的结果存在。在降低一级样品量的时候最小化离散误差的影响,就要求充分的物理混合,或在分析前随机化分布一级样品以提供均等的选择机会(以提取二级样品)。

Total Sampling Method Error 取样方法整体误差

Intrinsicor compositional heterogeneity is a function of the powder system and represents the true characteristics of the material (e.g., equation 3). Thus, intrinsic heterogeneity is often the minimal variance a system can have. The difference between the true state of the system and what is actually measured when ideal sampling is employed is called the fundamental error (equation 2). The relative variance of TSE (S2Total) is represented in equation 4 as the sum of the relative variances of all error components:

(颗粒)内在不均一或组成不均一属于粉体功能属性,代表了物料的真实性特征(见方程3)。如此,内在不均一经常是粉体所能有的最小离变性。粉体实际状态和基于理想样品的实测结果之前的差异称为基本误差(见方程2).整体取样误差(TSE)的方差 (S2Total)用方程4表示为所有误差成分的方差和。

The S2Total can be reduced by employing ideal sampling. Ideal sampling will limit or adjust for the effects of error contributed by particle segregation, extraction error created by the sampling device, delimitation error created by not considering the three-dimensional nature of the bulk material, and sample handling errors such as product degradation. The total variation is the sum of these sources of error, illustrated in equation 4 as independent, additive components. To the end of reducing these errors, an important goal of material characterization by sampling is the determination of the relevant errors within the bulk sample. Knowing the source of the error helps determine how to best minimize these errors.

整体取样误差方差( S2Total)可以通过利用理想样品的方式减低。理想样品可以限制或调节颗粒离散带来的误差影响,限制或调节取样工具导致的取样方式误差影响,限制或调节由于忽略大批物料三维特性导致的分界误差的影响,以及限制诸如产品降解的样品管理误差。总变异是所有这些误差因素的集合,如方程4表达的独立而相加的各因素。要降低这些误差的最后一点:通过取样表征物料的一个重要目的就在于测量批范围内的误差。了解清楚误差源对于确定如何最好降低这些误差会有所帮助。Fundamental error arises from the intrinsic heterogeneity of particles within a sample of the material population. Reducing fundamental error requires changing the intrinsic characteristics of the material, such as reducing the particle sizeby milling or grinding. Segregation error is the spatial distributional difference of particles across the population. This type of error can be minimized by mixing or randomization of the particles being selected. Segregation error is affected by the characteristics of fundamental error. Additionally, for the determination of both fundamental and segregation error, it is assumed that mechanical sampling is carried out correctly and is not invasive, i.e., that mechanical sampling does not alter the characteristics being measured and provides a true representation. In instances where sampling of the bulk material does not provide unbiased representation or is so invasive that it alters material characteristics, then, in order to obtain noninvasive, unbiased samples, operators may need to change sampling from a bulk form to a stream form of processing, either upstream or downstream from the sample point (see Appendix 2). The mechanical sampler may need to mix the sample sufficiently to facilitate random sampling with equal probability of selection in order to obtain an adequate representation of the entire bulk lot. The process may also require mixing or sampling from a location in the process that will provide a random sample from material that is susceptible to segregation.

基本误差会伴随整批批被抽样颗粒的内在不均一而上升。降低基本误差要求改变物料的本质特征,比如通过磨粉降低粒度。离散误差是整批颗粒的空间分布离变,这种误差可以通过混合和随机化被选取颗粒的方式减低。离散误差会被基本误差的特征影响,另外,对于评价基本误差和分散误差,机械取样应被正确应用而不应有破坏性,即机械取样不应改变被测属性并提供真实的代表性。比如取整批物料不提供无偏离的代表性或因具有太大破坏性而改变了物料的特征。因此,为了获得不带偏见,不具有破坏性的样品,取样员可能需要将从批量物料中取样的方式改为在加工过程中从物料流体中取样,既有取样点(见附件2)处顺流的,也有逆流的。机械取样可能需要充分混合样品以帮助实现均等几率方式随机取样,从而获得整批物料有充分代表性的取样。该过程也可能需要混合,或者从工艺流程的某一个点取样,这个点可以给对于离散敏感的物料提供随机的样品。

Extraction, delimitation, and handling errors occur as a result of the mechanical sampler and sample handling prior to analysis, which also are affected by fundamental error. Trends, shifts, and cycles are temporal sources of error that affecttotal error. The analytical error of the method of analysis contributes to the overall error of the reported result. In addition to obtaining representative subsamples from the bulk material, the method must also obtain a representative subsample from the particulate laboratory sample before analysis.

抽取、分界和操作误差的出现其实是样品分析前机械取样器和样品操作方式的结果,还受基本误差的影响。趋势、漂移和循环都是影响整体误差的即时因素。分析方法带来的误差也部分构成了最后结果的总误差。除了从大批量物料中获得有代表性样品之外,在执行样品分析之前也必须从实验室特定样品中获取有代表性的二级样品用于检验。

Sampling Strategy 取样策略

Atypical sampling strategy consists of two basic steps: (1) the primary or gross sample, followed by (2) the secondary sample, which reduces the primary sample to a size that is suitable for laboratory measurement. In short, the goal is to select from the lot a quantity of material suitable for measurement without significantly changing the attribute for which one is sampling. In parallel with the sample size reduction, sample size calculations must be done in such a way that the sampling strategy has sufficient statistical power to determine whether the attributes of interest lie within the specification ranges with a reasonable degree of certainty. Each step must be done correctly, or the sampling strategy as a whole will not provide a sample that is representative of the original population.

典型的取样策略包括两个基本步骤:(1)一级样品或总样品,然后是(2)二级样品,该样品将一级样品的量降低到适合实验室分析的水平。简而言之,目的是从批物料中选取适合量用于分析而不对被测属性造成显著影响。样品量的减少计算,应基于采用的取样策略具有足够的统计能力,可以使符合质量标准的被测结果有合理的可信度。每一步都必须正确应对,否则作为一个整体的取样策略无法提供对于原始批具有代表性的样品。

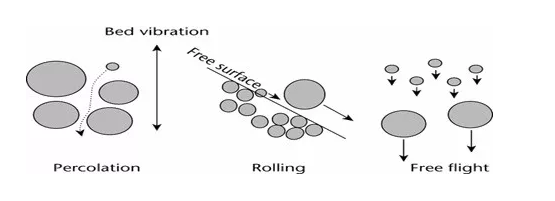

To successfully withdraw a sample from a bulk container that is representative of the population, one needs to have an idea of the population's heterogeneity, i.e., how segregated or stratified the system is. Knowing what factors can accentuate segregation and knowing the patterns of segregation that are likely will help one to account for segregation in a powder bed and to take better samples. Many factors can affect the degree of powder bed segregation. For segregation to occur, sufficient energy needs to be put into the powder bed to induce motion between particles. When a sufficient amount of energy is supplied, segregation can occur via three modes: percolation (in the powder bed), rolling (on the free surfaces of a powder bed), and free flight (when the powder bed is fluidized). These modes are illustrated in Figure 2.

为了从批包装中成功获取有整体代表性的样品,应对整体不均一性有基本的了解,比如粉体是如何离散或分层的。知道什么因素可以加重离散,知道离散的具体方式,这些可以帮助解读粉体的离散从而帮助获取更好的样品。许多因素都可以影响到粉体的离散度,对于离散的发生,需要针对粉体提供足够的动能以诱导颗粒间移动。当赋予了足够的动能,分散可以基于三种形式发生:(粉体内的)渗透、(粉体自由面的)滚动、还有自流(当粉体属于流体)。这些形式具体见图2.

Figure 2. Illustration of the three modes of particle segregation: percolation, rolling, and free flight.

图2. 颗粒分散的三种形式的演示:渗透、滚动,和自流

Within the powder bed, segregation can occur by means of percolation, also called sifting segregation, as well as through the movement of coarse particles to the top via vibration. During sifting segregation, smaller particles acting under the influence of gravity can more easily migrate downward into the void spaces between larger particles when the particle bed is perturbed. The net effect of these movements is that the smaller particles percolate down into the powder bed, resulting in the top of the powder bed having a higher proportion of larger particles. A common example of sifting segregation is unpopped cornkernels that are found at the bottom of a bag of popped popcorn.

在粉体内,离散可以渗透的方式发生,也称为过筛离散,就如同粗颗粒能以振动方式运动到顶部。在过筛离散过程中,当颗粒床振动时小颗粒在重力影响下可以更轻易的通过大颗粒的孔隙迁移到底部。这种运动造成的影响就是小颗粒振动到粉体底部从而导致颗粒床顶部有更高比例的大颗粒。一个通俗的过筛离散的例子就是可以在一袋爆玉米花的袋子底部找到没有爆开的玉米粒。

For free surfaces, rolling segregation can occur any time that particles can roll down a free surface. In other words, segregation can occur on any non-level surface that allows the relative movement of particles. When particles roll down these free surfaces, larger particles tend to tumble farther down the surface than the smaller particles (see Figure 3). For example, if a conical heap or pile is formed in the middle of a hopper during loading, larger particles are more likely to roll farther down the heap, toward the outer edge of the hopper. This creates a situation in which the smaller particles tend to be in the center of the hopper, and the larger particles accumulate toward the outer wall of the hopper. The formation of these free surfaces can be a major factor in segregation.

对于自由面,滚动离散可以在颗粒可以沿着自由面滚动的任何时候发生。换言之,在允许颗粒相对运动的任何非水平表面离散都可发生。当颗粒沿着这些自由面滚动时,大的颗粒会比小的颗粒“摔”的更远(见图3).比如,如果在装载过程中形成了锥体,大的颗粒更可能滚落到锥体下部外缘,这就造成了小的颗粒会在锥体的中心,而大的颗粒形成外墙。这种自由面的形成可以是离散的主要因素之一。

Figure 3. Example of extensive powder segregation within a drum.

图3. 桶内粉末大量离散示例

When powder beds are fluidized, a large amount of air is incorporated into the powder bed and, when this air is moving, the air velocity may exceed the terminal velocity of the smaller particles. When this happens, the fine particles are suspended in the air stream while the coarse particles settle out. The fine particles eventually settle on top of the powder bed, forming a top layer that has a higher concentration of fine particles. This type of segregation, sometimes called elutriation segregation, can occur when a powderis discharged from a hopper, or is poured into the top of a hopper, and a large volume of air is displaced.

当粉体流态化,大量的气体混入粉体。当空气流动时,流速可能超过小颗粒的终极速度。一旦发生这种情况,细颗粒就会悬浮在气流中而粗颗粒会沉降。细颗粒最终会沉降在粉体上部,从而在粉体形成一个有更高比例细颗粒的顶层。这种离散有时候叫淘洗离散,会在物料从漏斗内释出时发生;或者往漏斗里倾倒粉末,伴随相当体积的空气被置换时也会发生。

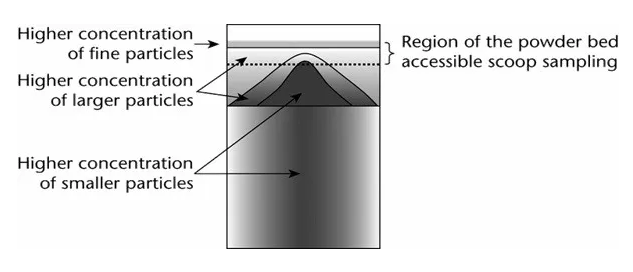

In summary, for a highly segregating system, the powder bed could have a particle distribution similar to that shown in Figure 3, where, as a result of elutriation segregation, a layer of fine particles on the top overlies larger particles deposited by percolation segregation, and aradial distribution of larger particles appears toward the outer wall as aresult of rolling segregation.

总之,对于高度离散的粉末系,粉体可能出现类似图3的颗粒分布。其中,作为淘洗离散的结果,粉体上方覆盖一层微粉;部分稍大颗粒以渗透分离的方式存在底部;还有更大颗粒在锥体外围以滚动分散的形式放射性分布。

In general, the primary factors that affect segregation are particle size and size distribution, density, and shape and shape distribution. Of secondary importance are surface roughness, surface coefficient of friction, moisturec ontent, and container shape and design. Particle size is the most important single factor, and subtle differences in particle size can cause measurable segregation. If the attribute of interest is associated with particle size,then this attribute will segregate along with the different particle sizes. For example, if a manufacturer makes a granulation in which the larger particles contain more drug than the smaller particles, then drug content can be very prone to segregation—i.e., drug content will show segregation patterns similar to those associated with particle size segregation.

一般而言,影响离散的首要因素在于粒度大小和粒度分布、颗粒密度、颗粒形状和形状分布。次要因素包括颗粒表面粗糙度,表面摩擦系数、水分含量、包装形态和设计。颗粒度是最重要的单一因素,颗粒度的细微差别都可以导致可测量的离散。如果被测属性和颗粒度相关,这个被测属性结果也会和不同的粒度大小伴随离散。比如,如果一个工厂制粒的大颗粒比小颗粒含有更多的活性成分,那么活性成分含量就有离散的倾向,即活性成分含量会体现和粒度分布离散近似的离散模式。

Segregation can notably increase sampling error because it decreases the probability that certain particle types will be in the sample. In addition, the powder bed may already be segregated when material is received, and poor sample handling can also cause segregation. To avoid further segregation during sample handling, the operator should avoid situations that promote segregation, such as the following: pouring where the powder forms a sloping surface, pouring into the core of a hopper, vibrations, shaking, and stirring (unless done to promote mixing). In addition, the use of mass flow hoppers reduces segregation.

离散可以显著增加取样误差,因为可以降低某个类型的颗粒存在于样品中的几率。另外,当物料被接收的时候,离散可能已在粉体中发生,而糟糕的样品处理也会造成离散。为了避免在样品处理过程中发生进一步的离散,取样员应避免促进离散的情形,比如避免形成颗粒坡面、避免倾倒进锥体、避免振动、摇动和搅动(除非为了促进混匀)。另外,密相流料斗可以减少离散。

Two basic strategies help promote ideal sampling: (1) use of a sampling thief and (2) sampling from a moving powder stream.

两个促进理想取样的基本策略:(1)刺入式取样,以及(2)从粉末流体中取样。

As ampling thief is a long spearlike probe that can be inserted into the powder bed and, once inserted, can collect powder samples from points adjacent to the spear. With a sampling thief, particles from almost any point in the powder bed can be included in the sample. The second method relies on fundamental principles of sampling, namely that (1) a powder should always be sampled when in motion, and (2) the whole stream of powder should be sampled for many short periods rather than sampling a part of the stream for a longer period.

刺入式取样器类似梭镖可以探入粉体,而且一旦刺入,可以收集梭镖毗连点的样品到取样器中。应用取样器,颗粒床的几乎任何点都有可能被收集到样品中。第二种方法依赖于取样的基本原则,即(1)总是在物料运动时取样,以及(2)粉末流应全程多时间点取样,而不是只在特定时间段。

For example, if the container to be sampled is emptied onto a conveyer belt, all the material will pass by a single point that can be sampled. Thus, no matter how segregated the system is, the collection of the powder at random time points ensures that every particle has an equal probability of being includedin the sample. The second fundamental principle accounts for material segregation on the conveyer belt: by collecting the entire stream, one gets across section of all the particles, no matter how much segregation occurs on the conveyer belt.

比如,如果一个将被取样的包装内物料被清空到传输带上,所有物料会通过可被取样的一点。这样,无论该粉体如何离散,所有粉末颗粒在随机时间点都能被取样,从而可以保证每个颗粒有均等的几率抽取为样品。第二个基本原则对物料在传输带上的离散具有意义:通过取整个流体,无论在传输带上发生了多大程度的离散,都可以获得所有颗粒的各个部分。Many methods are available for obtaining a sample from a powder system. Unfortunately, many of these methods involve setting the powder bed in motionor performing in-process sampling. Because of concerns about cross-contamination and containment of potentially toxic materials, most of these methods are impractical for the bulk sampling required for compliance with current Good Manufacturing Practices (cGMPs). Hence, most of the sampling done in the pharmaceutical industry is static sampling, done by either (1) scoop or grab sampling or (2) stratified sampling, typically employing a sampling thief. The choice of method is dictated by the distribution of the attribute being sampled in the container, as discussed below.

从粉体中取样有许多方法可供使用。很不幸,其中许多种是让颗粒床处于运动中时取样,或执行过程种取样。由于担心交叉污染,以及可能含有毒性物料,这些方法大多对于要求符合cGMP规则的散装取样不具有可操作性。因此,在制药工业,几乎所有的取样都是静态取样,以(1)勺铲取样或(2)层次取样,一般用刺入式取样器。方法的选择取决于取样待测属性在包装内的分布,详见下述。